We Are the Exclusive Dealer of the Barrel Blazer® Heating System

CLICK HERE FOR INSTRUCTIONS ON HOW TO SET UP AND OPERATE

When contractors try to process cold material, this can create a domino effect – the transfer pump fails to deliver material to the machine when it needs it, the machine goes off ratio, pressure sensors shut down the machine, error codes appear, the spray gun crosses over, and the applicator has sprayed a bad shot of material. At this point nobody is working until all is corrected resulting in hours of lost time and money. Learn more about the Barrel Blazer.

Buy NowIndustrial Drum Warmer: The Barrel Blazer® from SprayWorks Equipment

There are many types of drum warmers and heat wrapping devices on the market to choose from, but none of them heat at the source in the drum where the problem starts. The Barrel Blazer safely heats your material at the bottom of the drum where the materials are being pumped from, making it the ideal drum warmer solution available.

CLICK HERE TO VIEW OUR BROCHURE

Advantages of Our Industrial Drum Heaters

Offering upgradable units gives you more options for other products requiring higher drum temperatures. When other heat wrapping devices fail, contractors have no means of getting them repaired quickly and in most cases their only option is replacement.

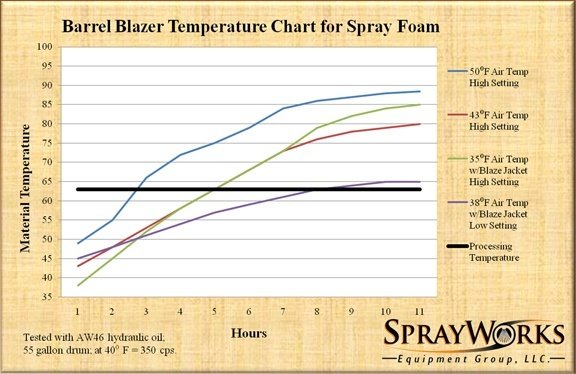

Another added benefit when using our industrial drum heater Barrel Blazer heating system is that the heat rises from the bottom of the drum to the top, therefore slowly agitating the material as well. The Barrel Blazer heating system will start paying for itself right out of the box, saving you not only in costly downtime. It will also help increase delta T’s performance and lessen the load on the primary heaters of the spray foam machine or polyurea machine you are using, resulting in higher yield gain that saves you money in lost product.

Finally, an industrial drum heater that is serviceable, dependable and works – the Barrel Blazer Spray Foam Material Warmer, exclusively from SprayWorks Equipment Group.

Check Out the Barrel Blazer Hot Plate Proof

Barrel Blazer® heats spray foam material by placing the drum onto a highly conductive drum size heating plate.

FAQs About Drum Heaters

What do my customers need a drum heater for?

Drum heaters help improve manufacturing processes because they keep materials at their needed temperatures. For example, keeping spray foam material at high temperatures is important because it keeps the material spraying as needed. Drum heaters ensure that your materials are heated and ready to be used in production.

What are the safety precautions that need to be followed when using a 55-gallon drum heater?

When using a 55-gallon drum heater it’s important to be cautious of heating elements to prevent accidents or injuries. Anyone working with a drum heater needs to read our manufacturer’s instructions to understand how the product works. Additionally, SprayWorks Equipment offers online, in-classroom, and on-site training so you can understand the safety process better using drum heaters in combination with your spray foam equipment.

We suggest keeping the heater on a solid, level surface so there is no chance of it being accidentally tipped over. Ensure your applicators understand that chemical reactions can occur at certain temperatures. Safety when using industrial drum heaters is highly important, and anyone working with one needs proper training.

What can be put in a drum heater?

In addition to heating spray foam and coating materials, drum heaters are great products when operators need to heat a large amount of resin or isocyanate.

Our 55-gallon drum heater creates a uniform flow of heat for these kinds of materials.

What other products does SprayWorks Equipment offer?

In addition to our industrial drum heaters, we provide the following:

- Spray foam proportioners

- Spraybots

- Spray guns

- Drum Mixers

- Transfer pumps

- Hoses

- Used spray foam equipment

Get your equipment from a trusted expert with over 100 years of industry experience.

The Barrel Blazer Spray Foam Materials Heating System Gets You Ready to Work Faster!

- Efficient, consistent heating – up to 4 heaters on a 20-amp breaker

- Fully serviceable, durable non-corrosive aluminum design provides lasting performance

- Dual element heating for reliable, fast-warming when time is critical

- Modular or bolt down mounting – easily installed in-plant, on-the-job or in your mobile polyurea or spray foam rig

- Low profile for compatibility with existing drum racks

- Safely secure drums during transport with the optional upright attachment

- UL recognized and CSA certified components

Contact SprayWorks Equipment to Learn More About Our Industrial Drum Heaters

For more information about our industrial drum warmer and heater options, contact our team at SprayWorks Equipment today!