Hydraulic Spray Foam and Coating Machines Need 5 Key Elements to Function

1. 220V/240V Single Phase or Three Phase Power Supply

Single Phase vs Three Phase determines how your power supply flows through your machine – a single conductor or three separate conductors. The more power required, the more conductors you will need. Three phase wiring setup is offered, but not required. It is often preferred because of the increased power required to run this setup. It will make the entire system more efficient if run on a three phase setup. The lower PSI machines like the Graco A-25 can run comfortably on a single phase setup.

2. Air Supply: Compressors

Air is used to actuate and/or purge the spray gun, drum pumps, mixer and/or actuate the machine itself if it’s an air driven type machine.

Air Compressor size and performance rating will be determined pending the system purchased ranging from 6 – 30 cfm at 100psi.

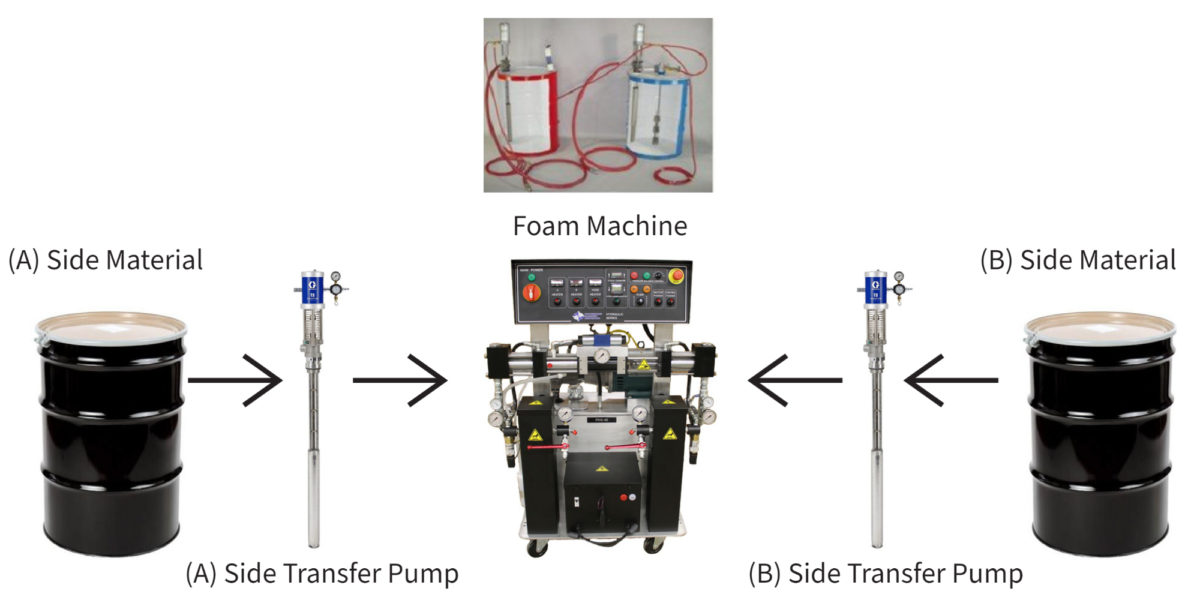

3. Transfer Pumps

Transfer pumps like the T3 (3:1) and P-52 (2:1) from Graco and PMC respectively are needed for each material in use (A & B Side for plural component setups). Coatings require a pump with a much higher ratio than this and only 1- since coatings are a single- component. These pumps move material from the barrel into the hose-lines leading into the proportioner or reactor where the materials are individually heated and pressurized to prepare to be mixed at the gun.

4. Heated Hose

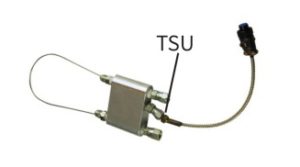

Material requires a specific temperature range to properly adhere and cure on its substrate. The chemicals also depend on a specific temperature and pressure range to react correctly producing ideal spray foam between the Iso and Resin blend. These temperature and pressure ranges will be noted in the Technical Data Sheet of your chosen material and is unique to each manufacturer inside of a generic range. Heated hoses help to evenly disperse heat along its entire length. Heated hoses typically come with wiring inside its scuff jacketing. The wiring must be protected from the elements. A TSU (temperature sensing unit) is connected and helps to regulate temperatures along the hose. When spraying foam – heated lines may run all the way to the end of the whip attaching to the gun. A & B chemicals are separate and must never interact until they reach the “mixing chamber” within the gun immediately before they exit the gun’s spray tip to be applied to the substrate.

5. Spray Gun

When material arrives at the gun, it shoots out when the trigger is actuated, this purges the material from the lines into the gun to be blended and exported onto the substrate. This is the moment when the chemical reaction of the A side and B side occurs. If polyurea is used, there is only one type of material used and no chemical reaction at the triggering of the gun. There are a few different types of spray guns to choose from, depending on your project type.

The machine is powered with and electric source 220v/240v to energize the control panel, hydraulic system and the heating system.

The machine will need to be supplied with materials; this is done by using transfer pumps to move the materials from 55 gallon drums to the machine. The transfer pumps are powered by air.

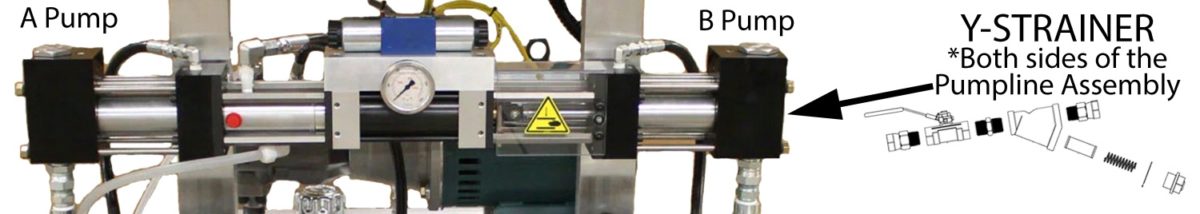

The materials are then pumped through a Y-strainer mounted to the main proportioner pumps at the machine to pre-screen any contaminants.

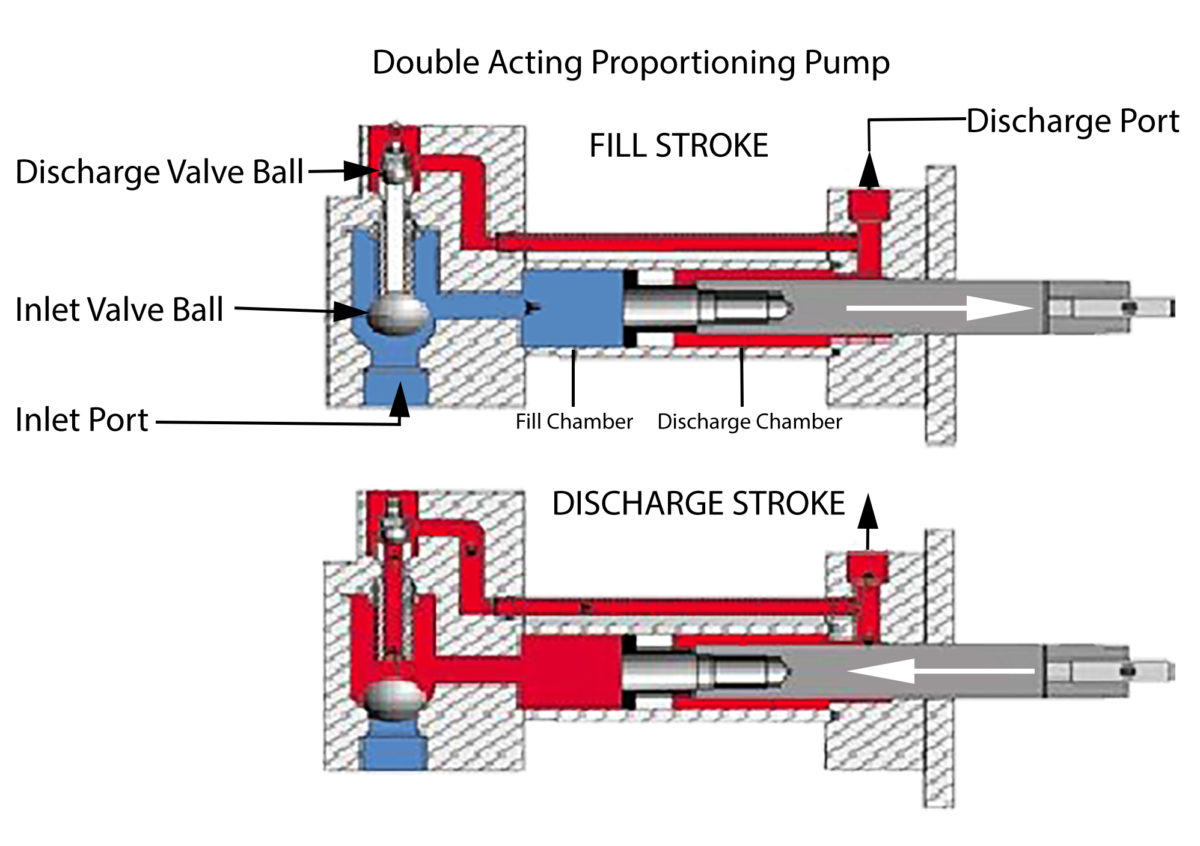

The A and B materials are then pressurized with the main proportioner pumps by an electric motor driving a hydraulic pump. (The Drive System).

The main proportioner pumps are double acting, creating positive displacement of material on both strokes.

After the materials are pressurized they are sent through a hose into heater blocks called (Pre-Heaters).

The Pre-Heaters are to set the (A) and (B) material temperatures to manufactures specifications.

Typical setting (pending manufactures) are 120F for closed cell foam and 130F for open cell foam.

From the Pre-Heaters the materials pressures are read with the pressure gauges and out to the spray hoses. Typical pressure settings starting around 1,000 psi.

The hose is to maintain the temperatures set at the Pre-Heaters to the manufactures specifications.

The red side of the hose is the (A) side material and the blue side of the hose is the (B) side.

Attached to the end of the hose is a temperature sensor unit called the (TSU).

The TSU senses the temperature of the material in the hose to show temperature at the control panel as well as to allow adjustments.

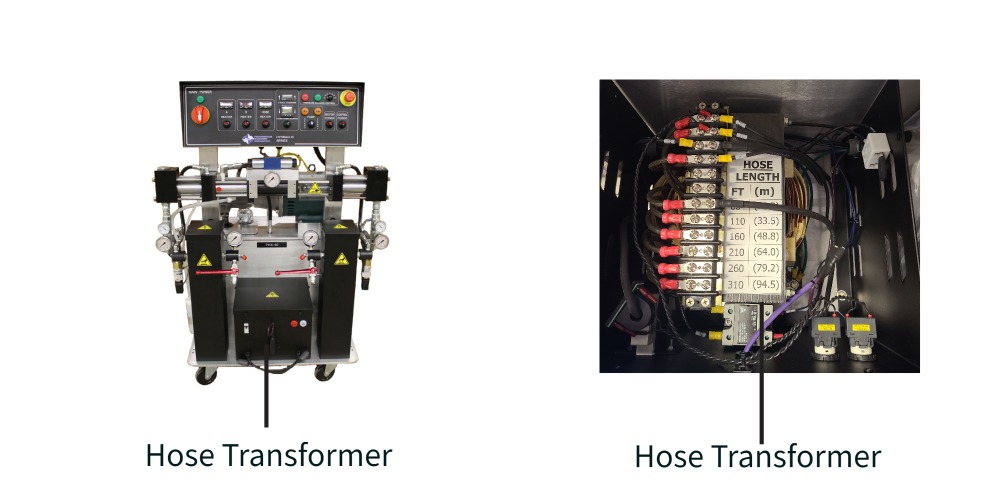

The heated hose gets power from a transformer located at the base of the machine.

Click here for our guide on How to Choose the Right Hose for your Machine.

The transformer has tap setting to allow for different lengths of spray hose.

The materials are kept separate until they reach the spray tip in the spray gun.

There are different types of spray guns; in this case we will use an Graco Fusion Air Purge Spray Gun.

The air purge gun is designed and powered by air to pull back the spray tip once the trigger is engaged allowing the (A) and (B) materials to be mixed at a 1:1 ratio.

Once the materials are mixed in the spray tip and the guns trigger is released, air purges through the mixing tip to clear the residual materials out.

LEARN THE DIFFERENCE BETWEEN A POLYUREA SPRAY MACHINE AND A SPRAY FOAM MACHINE