Sometimes, there are things you just learn over time. Our team of experts have shared some of the trade secrets they have learned through successes and failures.

Jim Davidson

Jim Davidson is the Managing Partner at SprayWorks Equipment Group. He has 50 years of experience in the spray foam industry and has worked alongside many of the industry pioneers. Jim has designed and created industry equipment such as; Spraybot, Barrel Blazer, Roboliner and Polybot - among others.

John Davidson

John Davidson is the VP of Operations at SprayWorks Equipment Group and is an SPFA PCP Certified Roofing and Insulation Installer, Roofing and Insulation Project Manager, and Supplier Rep. With over 30 years of experience in the spray foam and polyurea industry, John brings a wealth of knowledge and hands-on experience. He has worked on commercial and residential buildings, bridges and infrastructure.

Dave Penta

Dave Penta is the VP of Sales at SprayWorks Equipment Group. For the past 30+ years, Dave has worked with multiple industries including; commercial and residential buildings, along with spray foam and coatings systems.

SPRAY GUNS

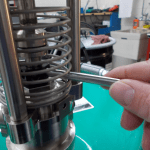

Check your A Filter

I make it a habit to check my A Filter before I start every morning. To me, that’s the only way I can pressurize the machine and accurately read gauges to eliminate any problems. The reason I check the A Filter in the morning is, regardless of when the gun is cleaned the previous day, the cleaner tends to leave a layer of film on the screen.

Spray Gun Safety

Every gun has a safety feature. You should get in the habit of turning on the safety feature whenever you stop spraying – whether it’s to talk to someone or check your depth. It’s an often overlooked step when a new applicator is learning, but can quickly cause serious injury or damage if the spray gun releases unmanaged chemical.

Spray Foam Equipment Thermal Expansion Hazard

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

HOSES

Keeping Material Warm

The Importance of Maintaining Daily Logs

Daily job logs are vital to the operation of your foam company because they are a true gauge of productivity, profitability and your break-even point. Job logs assist your staff in cultivating positive documentation habits of their day to day job activity.

This in turn helps you and your crew maintain expensive equipment, track costly material and supplies, assure customer satisfaction, give the true story of actual time and material versus planned time and material, lets you know which builders are properly accommodating your staff and tracks all vital manufacturer required information.

All this information is easily tracked in a document that takes less than 10 minutes to fill out per day. If you’ve ever been involved in a nasty job-site litigation you know this is 10 minutes a day very well spent.

Robert Quesnette is the Territory Sales Manager for the Northeast region at Rhino Linings. Robert has more than 25 years experience in the insulation industry. He founded and operated one of the first foam companies in Connecticut and has experience with client training, building science and code seminars.

Growing your business

Networking is Key

Whether you are new in the industry or a seasoned professional you should always network. Having and carrying business cards is a must. Handing them out at every meeting and event, like the Home & Garden Show or other local events, will help keep your name and info in the minds of potential customers or people who can connect you to the potential customers. Go to local networking opportunities and meet businesses who might not be in the spray foam/coatings industries but might be able to recommend you to a customer. Word of mouth is still extremely powerful.

TRANSFER PUMPS

Graco T3 Transfer Pump Packing

Changing Hydraulic Oil in your Spray Foam Machine

What you need to know before changing hydraulic oil is when operating in ambient temperature recommendations of 0 to 90°F (-17 to 32°C) frequency is about 1000 hours or 12 months, whichever comes first and/or in 90°F and above (32°C and above) 500 hours or 6 months, whichever comes first.

Recommended Oils:

Citgo A/W ISO Grade 46 Amsoil AWI ISO Grade 46 (synthetic*) BP Oil International Energol® HLP-HM, ISO Grade 46 Carl Bechem GmbH Staroil HVI 46 Castrol Hyspin AWS 46 Chevron Rykon® AW, ISO 46 Exxon Humble Hydraulic H, ISO Grade 46 Mobil Mobil DTE 25, ISO Grade 46 Shell Shell Tellus, ISO Grade 46 Texaco Texaco AW Hydraulic, ISO Grade 46 *

NOTE: After changing hydraulic oil and upon starting motor, hydraulic pumps may make a screeching noise until primed. If this noise continues for more than 30 seconds, switch off motor control and contact your machine manufacturer.

Don’t run out of material in your transfer pump

SCREENS & FILTERS

Filtering Chemical

Long ago (maybe 45 years) my old company evolved mostly into a spray foam roofing contractor from just an insulator. Because of the iso particles and small size screens, and yes, not doing a good job of sealing the iso drums. This was always a recipe for a pile of disaster. I kept shooting myself in the foot and no one would help to unload the gun.

Continue reading→Clean your screen filter

Materials entering the proportioning unit may require screening or filtering. Therefore, manufactures of the spray equipment commonly install y-strainers or filter housings on or near the machine to pre-screen the materials as they are transferred from the storage vessel prior to entering the proportioning unit. Proper cleaning or replacement of the screen filter must be completed daily or as needed to ensure proper material supply is achieved. Clogging and restriction of the screen filter may cause cavitation and/or poorly dispersed product known as off-ratio.

Continue reading→

WEATHER

Spray Foam Equipment Thermal Expansion Hazard

Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

Weather Conditions

As seasons begin to change, it’s easy to overlook the still-frigid-nights with the sunny days. Temperatures fluctuate from day to night, even in the spring and summer, so I recommend keeping your material stored and warm overnight. Don’t let the sun fool you!

Prepare for Cold Weather

With the cold weather quickly approaching and roughly 20 good working days between now and Thanksgiving, it’s important to make the most of product yield and production by being prepared. Make sure drums are warm and ready for the job by keeping them heated with products such as the Barrel Blazer heating system. Temps are dropping in evening, so container temps are going to drop. Plan ahead and be effective!

PROCESS & DOCUMENTATION

Ventilation at the Job Site

It may seem redundant but, when spray foaming, keep your job site ventilated and do it every single time you spray. Keeping the work area ventilated will prevent unnecessary exposure to fumes and particles that can cause damage to workers. Best practice is to be aware of the airflow and have a source of entry and a way for air to flow out of the work space. Also remember to keep the area ventilated until the re-entry time specified by the foam manufacturer.

For more information on proper ventilation procedures review the EPA Spray Foam Ventilation Guidelines

Properly Trained Team

Training doesn’t always have to take a ton of time out of your schedule. Taking one day to train a group of employees on proper equipment handling, maintenance or basic trouble shooting can prevent hours of lost time. Afterall, spending a few hours to train your crew on taking care of equipment can prevent having hours or even days of downtime due to a preventable mistake.

Daily Hose Maintenance

Daily hose maintenance is important to prevent your hoses form getting unnecessary damage and ensuring your hose and equipment last longer.

Continue reading→