Fluids subjected to heat in confined spaces, including hoses, can create a rapid rise in pressure due to the thermal expansion. Over-pressurization can result in equipment rupture and serious injury.

Author Archive: Dave Penta

What type of foam insulation spray equipment should I get?

When operating or are initiating a foam insulation business, you are aware of the practical, versatile, and lucrative nature of the insulation market. However, as with most booming industries, there are a variety of uses for spray foam insulation spanning a range of applications. In an increasingly ‘green’ initiative-minded world, insulation helps lower energy consumption and assists in keeping often unfriendly weather outside where it belongs.

Continue readingGraco T3 Transfer Pump Packing

Why Contractors are Interested in Turn-Key Spray Foam Rigs

Turn-key spray foam rigs are rigs that are ready to pick up and move on the job site for immediate use – as opposed to rigs that require additional setup in order to get them running. Various projects require different insulation needs, and it’s only normal for contractors to select the most efficient equipment when working.

Here, we will take you through the key reasons why contractors often prefer turn-key spray foam rigs to other insulation rigs. Besides the fact that turn-key serves a variety of purposes, it also comes with the needed use and training resources.

Continue readingChoosing the Right Spray Foam Systems

Selecting the right spray foam system is crucial. Your choice determines the overall success of your project, your business reputation, and the durability of the equipment you purchase.

Some contractors make the mistake of placing price over quality. Such decisions usually result in spray foam systems breaking during the course of a job. In some other cases, these low-quality products require excessive maintenance which contributes to increased repair costs.

With this reality, how do you ensure that the spray foam systems you purchase are high-quality, efficient, and long-lasting? Read on to find out.

Continue readingCheck Listing Your Air Compressor

Did you know your Air Compressor requires maintenance? Yes it does! There are a few simple steps you can take to elongate the life of your Air Compressor and keep it running smoothly.

How to Choose a Spray Foam Rig: A Brief Guide for 2024

Spray foam insulation companies work in residential, commercial, and industrial buildings using specialized equipment. Applying spray foam lets contractors create a seamless layer of insulation that seals cracks and gaps, which leads to lower energy consumption and a number of other benefits.

With the application of spray foam, property owners gain many benefits including improved energy efficiency, lower utility bills, better air quality, noise reduction, and more. There is a significant demand for these services, so starting your own spray foam business is a great way to fill the need. Doing so requires knowledge of the industry, of course, and this starts with knowing how to choose a spray rig.

Continue readingHow to Choose a Spray Gun Based on your Project Needs

Spray Guns Worth Mentioning

An essential part of Polyurethane application is having the right gun. In this article, we review the top seven types of Polyurethane applications, which gun is best, and why you should consider them for your next project.

Roof & Wall Insulation

Virtually any spray gun will work great for roofing and wall insulation. The Graco Fusion line is a popular choice, along with the PMC Air Purge line. Click here for more options.

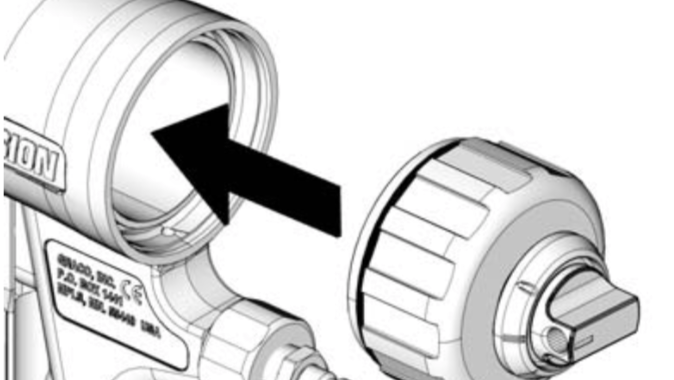

How to Easily Adjust the Output on Your Fusion Gun

Take your Machine from Zero to Full Flow

Continue reading

Introducing the New 20 Foot Roofing Rig

Low-Cost Roofing Rig for Spray Foam and Polyurea

Continue reading