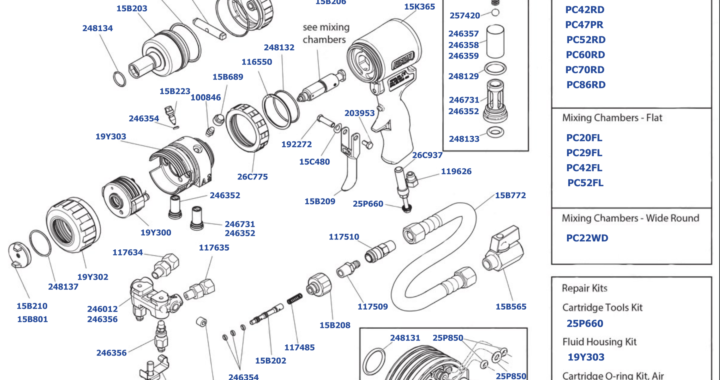

Use this parts finder to identify all the parts on your Graco Fusion PC Spray Gun with a direct link to the product on our store.

Author Archive: SprayWorks

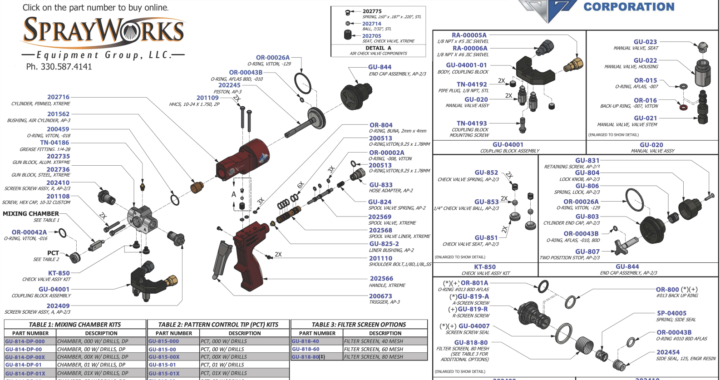

Parts Finder – PMC Xtreme

Use this parts finder to identify all the parts on your PMC Xtreme Spray Gun with a direct link to the product on our store.

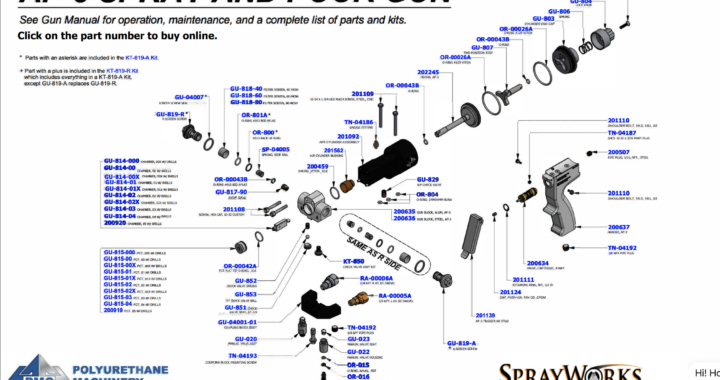

Parts Finder – PMC AP3

Use this parts finder to identify all the parts on your PMC AP3 Spray Gun with a direct link to the product on our store.

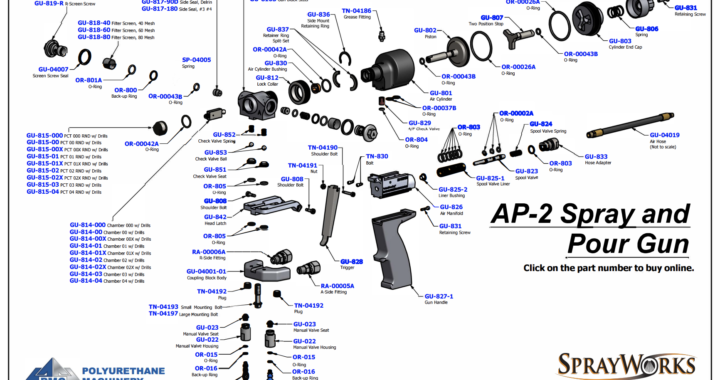

Parts Finder – PMC AP2

Use this parts finder to identify all the parts on your PMC AP2 Spray Gun with a direct link to the product on our store.

SprayWorks Introduces Roofing School as Part of its Educational Offerings

SprayWorks Equipment, a leading specialist in commercial single and plural component spray equipment, training and accessories, is launching its Roofing School to help business owners and their employees learn how to install, repair and re-new commercial roofs with polyurethane spray foam and protective coating systems.

Barrel Blazer Improvements Allow SprayWorks to Prevent Price Increase Due to Material Costs

SprayWorks Equipment, a leading specialist in single and plural component equipment, training, rigs, and parts, has redesigned the Barrel Blazer – a 55-gallon drum heater for polyurethane and polyurea materials.

With recent price increases in materials, SprayWorks was looking for a way to keep prices down for the Barrel Blazer. Adding fabrication to in-house services allowed outsourcing costs to decrease. Additionally, material use has been significantly reduced resulting in decreasing total weight of the Barrel Blazer by nine pounds. With improved design and decreased material use, heat circulation also improved.

The Barrel Blazer is often used in conjunction with barrel blankets for optimal warmth.

Continue readingSprayWorks Completes 2nd Acquisition with Trail Sprayer & Service

SprayWorks Equipment, a leading specialist in single and plural component equipment, training, rigs, and parts has completed its purchase of Trail Sprayer & Service, LLC.

Keeping Material Warm

The Right Transfer Pump

Having Quality Equipment

When starting your own spray foam company, it is important to have high quality equipment from reputable manufacturers. Companies like PMC and Graco have products that are quality tested and built to last. By spending more money on quality equipment now or buying new instead of used, you can save on having to replace less quality products more frequently. Oftentimes, used equipment is less costly than new because all the parts are brand new.