There are various types of safety boots and other personal protection equipment designed made and tested for protection from a wide variety of hazards at the workplace or other. Different professions have different hazard risk as well as different levels of risk. These hazards can be breaking the toe or metatarsal bones by falling or rolling objects, slippage, puncture wounds, electrical shock, chemical burns, frostbite and others. In the US, the rated safety shoes carry different symbols showing the protection level and type of protection they provide. They symbolize the results of various tests in accordance to different US and international standards which they have passed.

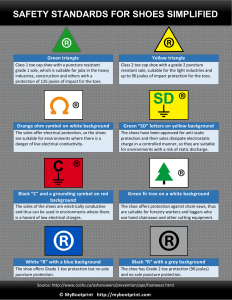

- R symbolizes the place where the name of the organization which did the testing and approval is placed. The color symbols used in the US and Canada to show the tested protection type and

level of protection:

- The green triangle symbolizes class 1 safety toe cap and puncture resistant soles. The toe cap resists to up to 125 joules. This footwear is great for construction, heavy industries, and other professions where there is danger of objects and tools falling and rolling on the foot, or where ther is danger of steping on sharp materials and items.

- A yellow triangle means that the safety footwear provides class 2 toe cap safety of up to 90 joules of impact, as well as a puncture resistant sole. These boots are perfect for lighter industries.

- The symbol with a white square with an orange omega sign indicates that the soles of the shoes are electrical hazard rated, which means that these shoes are suitable for professions and settings where there is danger of running into live electrical current

- The symbol which has a yellow square with the letters “SD” inside it indicates that the shoes have been tested and approved as anti-static, and also that their soles can dissipate electrostatic charge accumulated in a controlled manner, which means that they protect from release of static electricity.

- A symbol with a red square containing the letter “C” as well as the symbol for grounding indicates that the shoes have electro-conductive soles, so they are suitable for workplaces where there are risks of low electrical hazards.

- A symbol consisting of a white square with a green fir tree in it means that the boots provide protection against chainsaws and are suitable for loggers and other people who work with chainsaws and other dangerous cutting tools.

- A white letter “R” in a blue square means that the boots have class 1 toe protection (125 joules), but their soles are not puncture resistant.

- A symbol including a grey square with a black letter “R” in it, indicates that the shoes have class 2 (90 joules) toe protection, and no puncture resistant soles

- Top Characteristics of the Good Steel Toe Work Boots:

- Top Characteristics of the Good Composite toe boots

In the USA, safety shoes are tested by accredited laboratories for compliance to the US and international safety standards. Various accredited tests are performed to determine the type and level of protection the boots or shoes provide. Only after passing the tests successfully are the manufacturers allowed to place the symbol which corresponds to the type and level of protections the footwear provides.

Robert Quesnette is the Territory Sales Manager for the Northeast region at Rhino Linings. Robert has more than 25 years experience in the insulation industry. He founded and operated one of the first foam companies in Connecticut and has experience with client training, building science and code seminars.

level of protection:

level of protection: