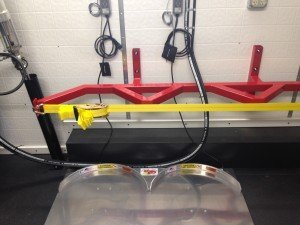

SprayWorks Equipment, a leading specialist in single and plural component equipment, training, rigs, and parts, has redesigned the Barrel Blazer – a 55-gallon drum heater for polyurethane and polyurea materials.

With recent price increases in materials, SprayWorks was looking for a way to keep prices down for the Barrel Blazer. Adding fabrication to in-house services allowed outsourcing costs to decrease. Additionally, material use has been significantly reduced resulting in decreasing total weight of the Barrel Blazer by nine pounds. With improved design and decreased material use, heat circulation also improved.

The Barrel Blazer is often used in conjunction with barrel blankets for optimal warmth.

Continue reading

Why should you keep your material warm? Quick and simple: Cold material is unusable. When it’s cold it thickens and damages your equipment. The best way to prevent this is using a drum warmer or insulation/barrel jacket. Using these stocked in your building or rig will keep your material warm and ready to use and prevent costly equipment repairs and/or replacements.

Why should you keep your material warm? Quick and simple: Cold material is unusable. When it’s cold it thickens and damages your equipment. The best way to prevent this is using a drum warmer or insulation/barrel jacket. Using these stocked in your building or rig will keep your material warm and ready to use and prevent costly equipment repairs and/or replacements.

Introducing the

Introducing the