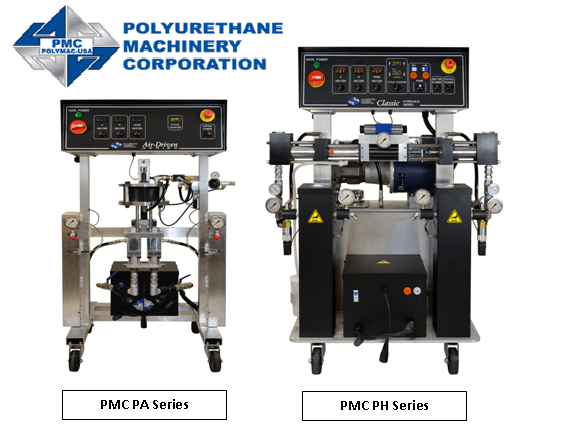

The new spray foam and coating machines from PMC.

The new PMC PA series was developed to provide the applicator with and economically priced machine that is user friendly, serviceable and designed to meet the modern day spray foam and fluid applied coatings requirements. The PMC PA series spray foam and coating machines will be available in two models. The PA-25-2000 and the PAX-25-3000.

The PA-25-2000 series spray foam machine is and air driven proportioner with and output of 25lbs/min and capable of up to 2,000PSI.

The PA-25-3000 series coating machine is and air driven proportioner with and output of 1.3 gal/min and capable of up to 3,000PSI.

The machine’s features a 7″ air motor , 7,500 watt heaters with the option of larger heaters. Weighing only 265lbs the PA series open frame design allows easy access to all of the major components. The PA and PAX machine’s also features state of the art reversing valve reversing the pump direction with out the need for electricity!

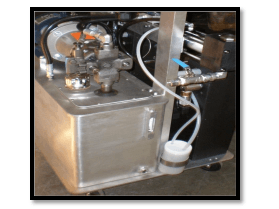

Inspecting the iso pump lubricant reservoir on your spray foam or Polyurea machine is often overlooked and should be part of a daily routine. Pump Lube forms a barrier between the ISO and the atmosphere. The lubricant will require changes pending the environment it is operating within. Typically every 3 to 4 weeks a gel formation occurs.

Inspecting the iso pump lubricant reservoir on your spray foam or Polyurea machine is often overlooked and should be part of a daily routine. Pump Lube forms a barrier between the ISO and the atmosphere. The lubricant will require changes pending the environment it is operating within. Typically every 3 to 4 weeks a gel formation occurs.