Tag Archives: spray gun

Having Quality Equipment

When starting your own spray foam company, it is important to have high quality equipment from reputable manufacturers. Companies like PMC and Graco have products that are quality tested and built to last. By spending more money on quality equipment now or buying new instead of used, you can save on having to replace less quality products more frequently. Oftentimes, used equipment is less costly than new because all the parts are brand new.

Guide for Selecting Roof Coating Spray Equipment

With roofing in high demand, it is essential to address any particular roofing issues to provide customers with the long-lasting protection they require for their substantial investment. A common question asked in the commercial roofing realm is, “What is the best type of roof coating to use?” The answer varies based on the factors being considered.

Maintaining Your Spray Gun

Tips for Cold Weather Spray Foam Insulation

With more customers requesting insulation installs for their residences and businesses, contractors are increasingly interested in finding out more about the application of spray foam. Many realized the benefits of spray foam insulation for cold weather as the frigid temperatures set in, resulting in calls to contractors who need to figure out how to maintain their foam product in temperatures not conducive to its operation and storage.

Continue readingMinimize Wear on Parts when Cleaning your Spray Gun

Although small, parts to your equipment can add up in cost. Some part costs are nominal, where some that do not require as frequent replacement, tend to be a little more expensive.

Torching, picking, sanding, and wire brushing off the gun and related parts often does more damage than good. At best, it cleans the parts but accelerates service wear by abrasive cleaning. Below are suggestions when performing regular rebuilds and cleaning your spray gun.

Continue readingHow to Choose a Spray Gun Based on your Project Needs

Spray Guns Worth Mentioning

An essential part of Polyurethane application is having the right gun. In this article, we review the top seven types of Polyurethane applications, which gun is best, and why you should consider them for your next project.

Roof & Wall Insulation

Virtually any spray gun will work great for roofing and wall insulation. The Graco Fusion line is a popular choice, along with the PMC Air Purge line. Click here for more options.

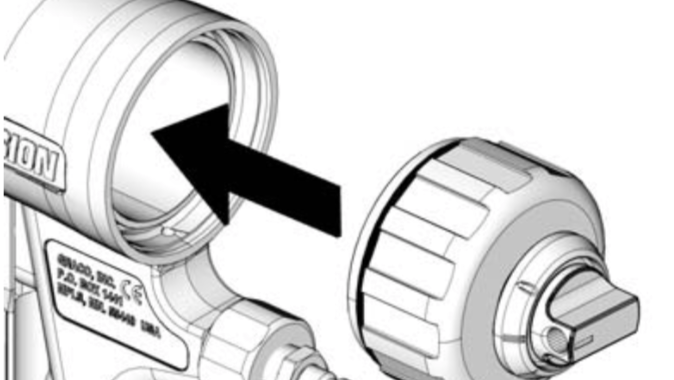

Fix-It Friday! How to Rebuild the Manual Valve

In this episode of Fix-It Friday! – we discuss how to rebuild the Manual Valve on your Coupling Block. PMC’s Coupling Block features rebuildable valves, which allow you to better maintenance your block.

6 Ways to Enhance your Spray Gun

You have your spray gun, now what? Different jobs require different mixing chambers and variable pressure from your machine. Your gun requires care and maintenance in order to extend the life of the gun. Here, we discuss the top six gun enhancements you should have on-hand in order to enhance and extend the life of your spray gun.

How to Easily Adjust the Output on Your Fusion Gun

Take your Machine from Zero to Full Flow

Continue reading