Which each spray foam project, your goal is to not only complete the task but to keep everyone safe and ensure the surrounding area is as clean as possible. But sometimes accidents happen. In these situations, it is critical to show that you are knowledgeable about the clean-up process and capable of conducting it.

Author Archive: John Davidson

How to Remove Spray Foam Overspray from Cars

8 Easy Steps to Removing Spray Foam Overspray from Vehicles

In this episode of Fix-It Friday our spray foam expert, John Davidson, teaches you how to remove overspray from cars. Preventing spray foam overspray is always the best first step, but we realize accidents happen and sometimes the wind hits just right. Learn what the best clay bar for overspray is, how to remove overspray from cars, and other tips on communicating with the owner of the vehicle.

Continue readingHow to Prevent Crystallization in Spray Foam Equipment

Taking proper measures to prevent crystallization in spray foam equipment can minimize your downtime while leaving your customers with results they are highly satisfied with.

In order to effectively prevent spray foam crystallization, be sure to understand the signs of crystals and how to get your equipment back up and running. In this post, we discuss what crystals look like, the complications they cause, and how to keep them at bay.

The Benefits of Polyurea Coatings

Polyurea coatings are used to prolong the lifespan of structures by providing them with qualities that result in reduced repairs and replacements. They do this by adding a waterproof and weatherproof seal that increases durability and longevity.

Continue readingTips for Creating Concrete Estimates for Your General Contractor Business

While there is no art to creating accurate estimates for your construction job, it does require thoroughness and attention to detail to ensure that you not only cover the costs involved but, you also make the profits you’re after too. Challenging as it may be, here are some helpful tips to create concrete estimates for your next project.

Continue readingNeed Roofing Spray Foam? Here Are 5 Reasons to Choose SprayWorks

When you are trying to improve energy efficiency and attempting to achieve comfortable temperatures in buildings, applying roofing spray foam can be greatly beneficial.

Whether you are in the market for residential roofing spray foam or commercial roofing foam, SprayWorks is a trusted supplier for your project.

Continue readingJune is National Safety Month

Safety should always be top of mind, but National Safety Month is a reminder to review your safety plan, educate employees on safety requirements, review and replace PPE, and be vigilant of safety risks.

Continue readingFalls account for 33% of all construction deaths, and eliminating falls in construction would save more than 300 lives every year.

BLS

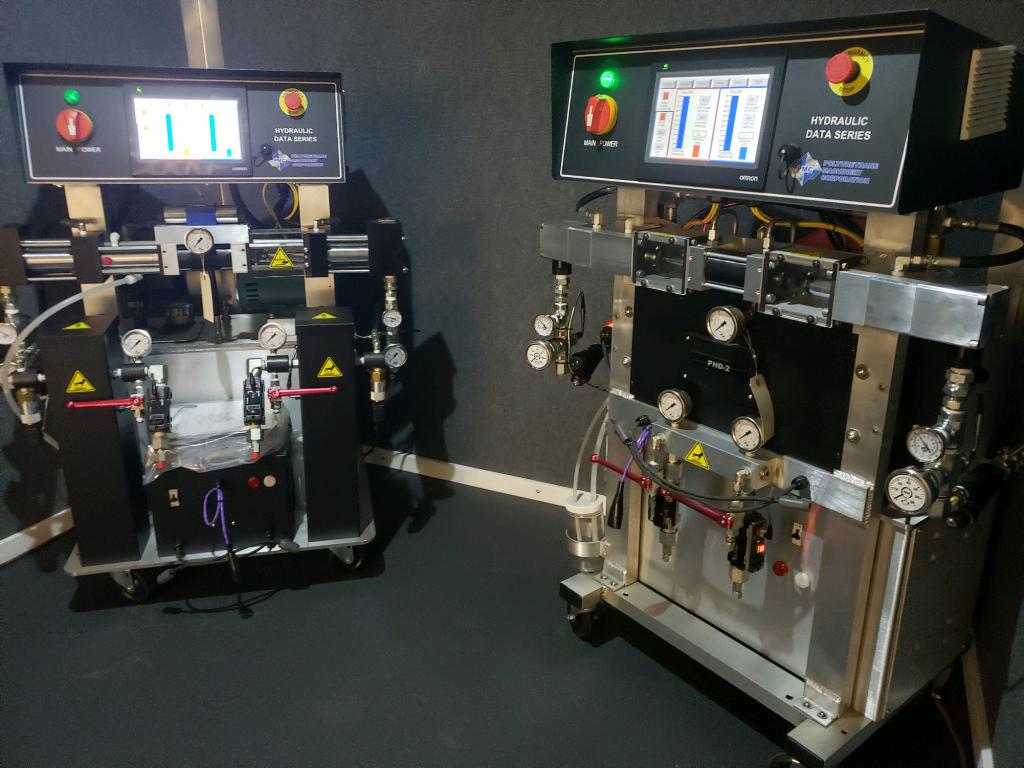

The Difference Between a Polyurea Spray Machine and a Spray Foam Machine

Choosing the right equipment is vital to a business that operates in spraying material for insulation and coating projects. The ability to perform a job effectively often hinges on the equipment or tool it is performed with, so it is important to understand the different types of spray machinery in order to adequately perform a job.

Continue readingWhen to Perform Maintenance Checks

Avoid unnecessary down time by performing maintenance checks before you start your day. It is easier to perform these checks while the system is cool and pressure free. Taking this step saves you downtime later if something was wrong.

Maintaining Your Spray Gun