SprayWorks Equipment, a spray foam and coatings equipment company, is celebrating 15 years in business. The business began in 2008, with Owner, Jim Davidson and his wife, Debbie – along with just a few employees. The company grew out of three buildings over the years and has since gained 40 employees.

Author Archive: SprayWorks

Spray Foam Convention in Las Vegas!

Booth #607 at the Spray Foam Convention!

Join us in Las Vegas from March 5-6, 2024 for the Spray Foam Convention!

Tuesday, March 5, 2024 2:00pm-6:00pm

Wednesday, March 6, 2024 2:00pm-5:00pm

- Meet the Experts

- Show Specials

- Freebies and Giveaways

- New Equipment

Troubleshooting Hose Heat with the PMC PK-25

In this episode of Fix-It Friday, we teach you how to identify and fix issues with your spray foam hose heating system using a PMC PK-25 spray foam machine. Hose heat is the biggest technical support issue we get and there are a few common issues that can be easily identified and resolved while on the job site.Continue reading

PMC Proportioner Technical Service Bulletin

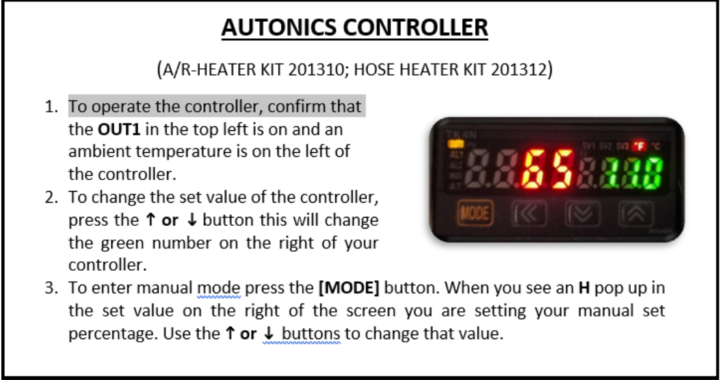

The new Autonics controllers are a slightly different look for proportioners PMC built in 2023 and beyond.

the Set Point will still be on the Right-hand side and the system temperature will be on the Left. You will still raise and lower the Set Points with arrows as before and, if you need to use the Manual Hose Heat function, you just push the MODE button and, you will see a H pop up then, using the up arrow increase the power percentage value as needed.

Also to be noted is that the Part Numbers for the controllers will continue to stay the same: A&B PN#201154, Hose PN#201155.

PMC PK-25 Proportioner Service Manual

Careful study of this manual will enable the operator to know the characteristics of the PK Series Proportioner and the operating procedures. By following the instructions and recommendations contained herein, you will reduce the potential risk of accidents in the installation, use, and maintenance of the PK Series Proportioner. You will provide a better opportunity for greater output, incident-free operation for a longer time, and the possibility of detecting and resolving problems quickly and simply.

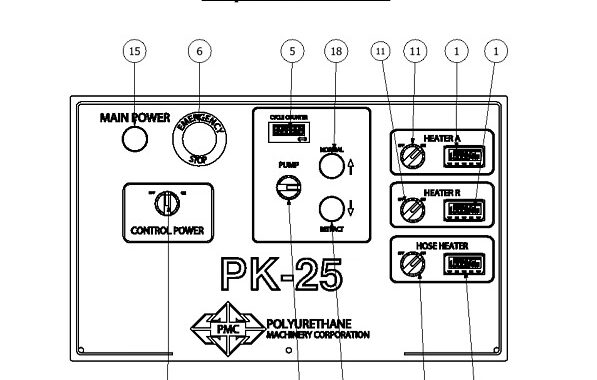

PMC PK-25 Proportioner Electrical Drawings

This manual contains important information on the safety, handling, and use of your PK Series Proportioner.

SprayWorks Conducts Spray Foam Testing on Behalf of Natural Polymers

SprayWorks Equipment recently worked with Natural Polymers to test spray foam materials from across the country. The application portion of the test was conducted at the SprayWorks Equipment facility in Kent, Ohio. After Owens Corning’s 2022 acquisition of Natural Polymers, an Illinois-based spray foam manufacturer, the company sought a location to carry out customer focused learnings.

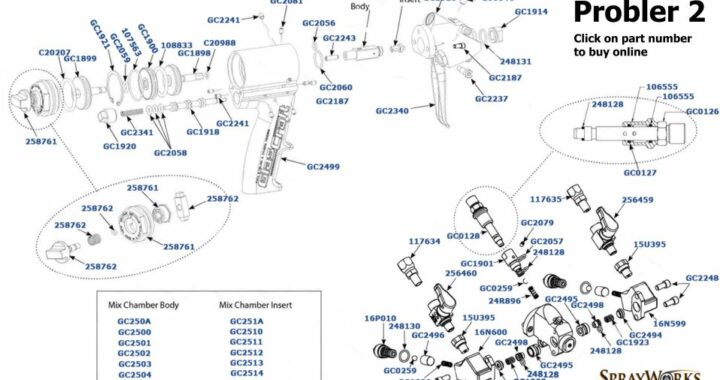

Continue readingParts Finder – Graco Probler 2

Use this parts finder to identify all the parts on your Graco Probler 2 Spray Gun with a direct link to the product on our store.

SprayWorks Begins Offering HFO Foam to Support Contractors with HFC Compliance

SprayWorks Equipment recently began offering foam containing hydrofluoroolefin (HFO). Many states now require spray foam applicators to use closed cell foam that does not contain hydrofluorocarbon (HFC).

Continue reading2023 Spray Foam Convention & Expo

It’s time for the Spray Foam Convention & Expo! Whether you’ve attended before or this is your first time, plan on an educational week full of industry experts and leading industry equipment.

Continue reading