Spray polyurethane foam material is one of the ongoing expenses you’ll have as an equipment and business owner. That means it’s one of the biggest areas in your business that you can cut costs by reducing waste when storing or spraying SPF material. Use the following four tips to effectively minimize SPF material waste in your spray foam insulation business.

Tip #1: Keep Material Warm

When spray foam material gets cold, it becomes unusable. As the temperature of the material drops, it thickens, and this viscosity can damage your spray gun and create even more complications, as the failure to deliver material to the machine will cause it to go off ratio, induce error codes, and set off the pressure sensors. If the applicator sprays a bad shot of material, it can result in lost time and money, essentially doubling the impact on your bottom line. We recommend the Barrel Blazer, which heats the material at the bottom of the drum, where material is first drawn from. Barrel Blazer heating systems lighten the load of primary heating systems and keep your foam material warm throughout, resulting in higher yield and less lost product.

Tip #2: Use the Right Pump

Getting all the material from the bottom of the drum helps you use every bit of product so you can save money on replacing material. Choosing the right transfer pump for your job is crucial to your success, as it’s important to check the pump’s design and ensure it can handle the spray foam material or coating material you are using. SprayWorks offers PMC 2:1 Transfer Pump – a pump newly redesigned for higher viscosities, easier cleaning, and varying pump lengths. This pump can apply polyurethane, Polyurea, and two additional component materials, and the interchangeable pump lengths fit up to a 250-gallon drum.

Tip #3: Prevent Moisture in the Drum

Moisture causes iso crystals to form, blocking the drum, hose and other components, ultimately destroying both the SPF material and equipment. Stopping iso crystals before they form means preventing any moisture from settling into the drum. We attach a Desiccant Dryer to our drums to remove moisture from the air during pumping. That stops the moisture from causing iso crystals, ultimately clogging the filters and prematurely curing the material while it’s still inside the hoses.

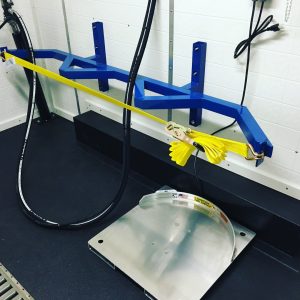

Tip #4: Transfer Material Correctly

Getting all the material out of the hose and returning it to the drum when changing material can help your bottom line as well. Our Logan Manifold can make change-over of material simple, whether using open or closed-cell foam, and can save $175 on average, during every material change. The Logan Manifold uses a simple process that prevents cross-contamination by pushing material back into the correct drum.