Regardless of the product or project, the expectation is always seamless performance. In order to promote this, proper maintenance is essential, and this could mean replacement, remodeling, or repairs.

Continue readingTag Archives: Graco

Having Quality Equipment

When starting your own spray foam company, it is important to have high quality equipment from reputable manufacturers. Companies like PMC and Graco have products that are quality tested and built to last. By spending more money on quality equipment now or buying new instead of used, you can save on having to replace less quality products more frequently. Oftentimes, used equipment is less costly than new because all the parts are brand new.

2021 Guide to Expanding your Business with your Spray Foam Equipment

If you own a spray foam business, you have likely invested in a rig. This gives you a central location for easily transporting all of your service equipment regardless of what your customer’s needs might be. However, it is just as likely that in your business operations you have encountered customers who need other services performed, ones you simply cannot help out with as you are missing the needed equipment which could be supplemented to your rig’s collective. If you just had a few more pieces of equipment, you could potentially offer multiple other commonly requested residential services, supplementing your business model’s array of services.

Continue readingDave Penta Celebrates 35 Years in Polyurethanes

SprayWorks Equipment Group is proud to celebrate its VP of Sales, Dave Penta. Dave has worked alongside some of the most experienced spray foam and coatings applicators in the Polyurethane Industry. His experience includes; commercial and residential buildings, along with spray foam and coatings systems on innumerable substrates.

Dave started his career working on projects with his Grandfather, Wayland “Dave” Davidson and Uncle, Jim Davidson (Owner, SprayWorks Equipment). He has worked on some of the most historical buildings in the Akron/Canton area in addition to major projects all over the United States.

I’m proud to work alongside my nephew, Dave brings a wealth of knowledge to our customers and is just as passionate about the industry as I am.

Jim Davidson, Owner, SprayWorks Equipment Group

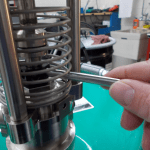

Graco T3 Transfer Pump Packing

Troubleshooting Graco Reactor and PMC Proportioner Machines

Effective troubleshooting requires several elements that can be developed. The single most important requirement, without a doubt, is to have an understanding of the function of each component, its importance, and how it functions – and all of these steps should be learned in a basic training. Once these basic functions are understood, the rest becomes a simple matter of applying logic or “common sense”. Here are some basic issues that typically occur on common Graco and PMC machines and how to correct them.

Continue readingProduct Review: Graco T3 Transfer Pump

The Graco T3 Transfer Pump is the newest Transfer Pump from Graco, Inc. This quiet 3:1 pump can accommodate low ceiling heights at only 50.3″ and low weight at only 22 lbs.

Continue readingHow to Choose a Spray Gun Based on your Project Needs

Spray Guns Worth Mentioning

An essential part of Polyurethane application is having the right gun. In this article, we review the top seven types of Polyurethane applications, which gun is best, and why you should consider them for your next project.

Roof & Wall Insulation

Virtually any spray gun will work great for roofing and wall insulation. The Graco Fusion line is a popular choice, along with the PMC Air Purge line. Click here for more options.

Fix-It Friday! How to Rebuild the Manual Valve

In this episode of Fix-It Friday! – we discuss how to rebuild the Manual Valve on your Coupling Block. PMC’s Coupling Block features rebuildable valves, which allow you to better maintenance your block.

Summer Machine Trade-In Special!

Now through August 31, 2018 – trade in any proportioner and get $3,000 off a new PMC PH-2 Proportioner.

We’ll take any proportioner in any condition! The PH2 Proportioner is a hydraulic machine with 28 lbs/minute output and max psi of 2,000. It can withstand up to 410 feet of hose and is perfect for any spray foam project including; attics, crawl spaces, residential insulation, storage tanks, roofs, and more. Also available for coatings projects with the PHX2 machine. This machine is economically priced with an open frame that makes it lightweight and capable of withstanding the long term needs of high pressure projects.

Continue reading